Silicone render is a frequently opted variety for shielding a construction from weathers. It provides a long-lasting, attractive finish that can be maintained for many years. In this post, we’re going to discuss what silicone render is, how silicone render is applied, and what the advantages of silicone render are compared to other render finishes such as acrylic render.

What is Silicone Render?

Silicone render is an external wall coating where silicone resins are used as a principle component. These resins are what make the render unique, offering high water resistance and flexibility. The breathability of silicone render is different to typical cement renders – this means it is functional in terms of excess inward-bound moisture being released from the building fabric whilst preventing water from entering. So, it allows for proper airflow and keeps dry, and your condensation issues should go away.

Some of the main advantages of using silicone render are:

- Water Repellent: Its repellant dealings with moisture are due to a natural water-repellent silicon coating, which helps keep water from saturating walls, which would otherwise cause weathering.

- Flexible: The silicone resins used to make the render allow it to stretch more than normal renders. This flexibility can help prevent cracks caused by building movement or temperature changes.

- Breathable: The building is able to breathe out any water vapour that enters and prevent the occurrence of damp and mold.

- Durable: Silicone renders do not fade, stain or get sun damaged, meaning they will look their best for years to come.

- Ease of Care: A silicone render will repel water from its surface and be simple to clean and maintain.

Advantages of Applying Silicone Render

Weather Resistance

Excellent weather resistance is offered by the silicone render. Since the silicone resins are hydrophobic, water beads and rolls off the surface without wicking into the walls. This is more significant in high rainfall or adverse weather conditions. The render is a great safeguard against freeze-thaw damage which can cause cracks and spalling in rival types of renders.

Does Silicone Render Damp Proof or Waterproof?

Yes, silicone render is waterproof. Due to its water resistance, it is a good defence mechanism against water and rain to prevent the house from water damage.

Flexibility and Anti-crack Properties

The flexibility of silicone render is one of its key benefits. The old and traditional cement render products will fracture if the building moves slightly or there are changes in temperature. The silicone resins in silicone render are able to have more stretch in it and can flex slightly with a property, without cracking. This will keep the render looking and performing like new.

Breathability and Moisture Prevention

Silicone render is permeable to water vapor that finds its way out of the building. This matters because a wall’s interior can collect moisture through condensation, leaks or rising damp. Moisture buildup is a problem because, if the moisture cannot get out, you are going to have a wet environment, mold, or even other property damage. Silicone render lets walls breathe, so minimises the risk of the above.

Easy to Clean and Reliable

Silicone finishes are meant to endure so they require little attention over the years. They will not be damaged by UV or fade, and will retain their color in all weather. The water-resistant surface also wipes clean. Typically, hosing the walls to remove dirt and grime will suffice.

Aesthetic Appeal

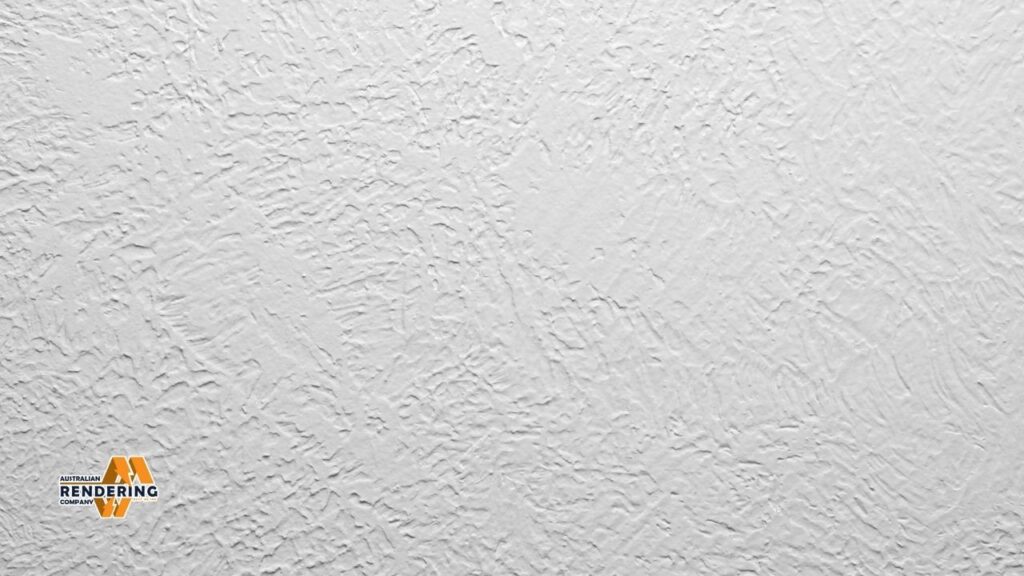

As the colours are mixed into the render, it should be noted that there are also a greater variety of colours on offer than brick slip, and it is also available in a number of textures, enabling you to really up the uniqueness of your property. Ideal for application to most surfaces; such as brick, block, concrete and plaster. The finish of silicone render is smooth and flat, which would enhance any wall or façade.

Silicone Render vs. Other Rendering Options

Is Silicone Render Superior to Acrylic Render?

Types of render – Silicone v Acrylic: Silicone render and acrylic render are two of the top picks when it comes to external wall coatings; however, they each have their own set of features and benefits. Is silicone render better than acrylic? It varies based on what your project requires.

Acrylic Render: Acrylic render is usually cheaper than silicone render. It is also highly flexible and impervious to digging. But unlike silicone render, acrylic isn’t as breathable or water-proof. That means it may not be the best siding type for buildings in rainy climates or for other dwellings susceptible to moisture.

Silicone Render: Silicone render, meanwhile, can provide better resistance to water while also achieving breathability. It is also more tough and stain-resistant. That being said, it usually costs a bit more than acrylic render. Silicone render is suitable because of its higher flexibility and elasticity which is best for buildings that need high protection against the elements and one that requires breathability.

Here is a quick comparison:

| Feature | Silicone Render | Acrylic Render |

| Price | Higher | Lower |

| Water Resistance | Excellent | Good |

| Breathability | Excellent | Moderate |

| Flexibility | Very Good | Excellent |

| Durability | Excellent | Very Good |

| Stain Resistance | Excellent | Good |

Cement Render

Cement render is the most common type of render consisting of a sand and cement mix. It’s sturdy and tough, but it’s rigid and easily broken. Cement render, being non-breathable, can hold moisture within walls, causing damp and mould. Silicone render is an excellent choice for buildings which demand both water repellence and the ability to breathe.

Lime Render

Lime Render is another of the traditional renders made using lime, sand and water. It is not as durable as cement render, and less resistant to rain and frost. Silicone render gives a nice mix of breathability and durability, and is a frequent choice for new builds and renovations.

Cost of Silicone Render and How to Apply It

Silicone Render Price

The cost of Silicone render can depend on the size of the area you want to render, the type of silicone render, and the amount of effort needed. In general, the cost of silicone render is higher than that of acrylic or cement due to the former’s high price silicone resins. Also, the quality of the substrate can influence silicone render work.

To obtain a realistic cost for silicone render, the ideal solution is to obtain three or four quotes from rendering specialists. They can determine your individual requirements and give you a comprehensive summary of costs. As a general rule of thumb, you will be paying more per square metre for silicone render than other types of render.

How to Apply Silicone Render

The application of silicone render is a multi-step process that will help ensure a long-lasting, weatherproof and smooth finish. Although you can take a DIY approach, hiring a professional rendering contractor is often best because the job will be done right the first time.

Below are the key points in how to apply silicone render:

- Preparation of Surface: The surface on which the waterproofing compound is to be applied (both new and old) should be thoroughly cleaned from oil, grease, dust, loose particles etc. Any opening or gap must be fixed prior to applying the render.

- Preparation: A primer is required prior to applying the system to help adhesion and form a consistent base for the render. The selection of primer will vary based on the substrate.

- Base Coat: A base coat of render is added to the surface. This coat will give you a smooth base for the last coat of silicone render.

- Mesh Reinforcement (Optional): Sometimes a mesh reinforcement is incorporated into the base coat for added reinforcement to resist cracking.

- Application of Silicone Render: The silicone render is then applied to the substrate in one or two coats, depending on the texture and finish required. The coating is generally applied by way of a trowel or a mechanical spray machine.

- Finish: After the render has been installed, the finish is applied for the desired texture. That is to say, this can be done in numerous ways.

Note: The K-rend silicone render application, or any other brand, will have different guidelines to follow, but the application technique and mix preparation are similar so always refer to the manufacturer’s advice.

How Long Does It Take for Silicone Render to Dry?

The duration of how long silicone render takes to dry will depend on factors such as weather, the thickness of the render and the type of silicone render being used. In general, you will need to leave between 24-72 hours for your render to dry to the touch. But it will be a few weeks before the render fully cures and attains its maximum strength and resistance to water.

It’s essential to guard the render against rain and frost while it is drying. Plastic sheeting over the rendered surface provides added protection against damage and ensures correct drying.

How to Care for Silicone Rendered Surfaces

How to Clean Silicone Render

Another advantage of silicone render is that it can be maintained pretty easily. The water-repellent coating keeps dirt and grease from adhering, so it typically requires cleaning only occasionally. Cleaning silicone render generally involves the following steps:

- Hose Down: Rinse the surface with clean water to remove dirt and debris.

- Gentle Cleanser: If it is soiled, clean with soap or mild detergent. Wash the detergent with a soft brush or sponge.

- Rinse Well: Rinse the surface well with cool water to get rid of any detergent residues.

- Pressure Washer (Optional): A pressure washer on the lowest setting can be used for tough dirt. Just take care not to rub the render away!

Repairing Silicone Render

While silicone render is rugged, it can still suffer the consequences of a crash or mistake. Minor damage is often easy to repair. If the scale of deterioration is extensive then the whole section of render may need to be renewed. If you are going to have any work done, make sure you use an experienced rendering contractor who will replace any damaged rendering with a high-quality, neat finish.

Australian Rendering Company is your professional rendering in Melbourne, whether it’s acrylic, cement, or even cladding. With over 30 years of know-how, they produce durable and clean finishes for your new home, renovation, or repair that all come with a 7-year warranty. You can reach them at 0466 943 872 or contact@australianrenderingcompany.com.au for further details.

Conclusion

The Benefits of Silicone Rendering: Silicone rendering has several advantages for shielding a building from the elements. It provides the perfect level of waterproofing, versatility, breathability and strength for new construction and renovation. This option may be costlier initially, but it is undeniable that its long-term benefits and maintenance-free nature make it a proverbial investment.

So is silicone rendering ideal for you?

If you are looking to render your property, silicone rendering is something to consider. It is a long-lasting, stylish and low-maintenance option which can stay put for years of exposure to the elements. Why not speak to a qualified rendering contractor to discuss the needs of your property and see if silicone rendering is the perfect option for your home.

The Pros of Using a Professional Silicone Rendering Specialist

There are a number of benefits to hiring a professional contractor when it comes to achieving a high quality, long-lasting finish so that your property is protected. Here are some key benefits:

- Knowledge and Skills: Professional contractors are knowledgeable and skilled in silicone render applications; they simply know how to get the job done without delays.

- Good Surface Preparation: Proper surface preparation is key to good adhesion and durability of the render. Experts also understand the process of cleaning, priming and preparing different surfaces to make sure the render is applied to a good, solid base.

- Premium Materials: Skilled professionals work with top quality silicone render materials and tools, providing an excellent finish that is long-lasting and visually appealing.

- Fast Application: When using the correct tools and methods, experienced installers can have silicone rendering applied in next to no time, reducing any inconvenience to your home.

- Warranty and Support: The majority of reputable rendering agencies will offer a warranty on both the work carried out and materials used, so a little peace of mind in the form of protection against potential future issues.

- Price: Hiring a pro may seem costlier at first, but in the long run, it can save you a lot if you do not like the finish you applied, or if it doesn’t last.

How long does silicone render last?

Silicone render can work great for 20 years or longer if it’s well applied and kept up. It is weather-resistant and comes with a long life-expectancy as an alternative to an exterior wall coating.

Can you paint silicone render?

Indeed, silicone render can be painted, but it is a good idea to only use paint which has been designed to adhere to a silicone render. These paints are often breathable and flexible, moving with the render so there is no cracking or peeling.

Can silicone render be used for any type of property?

Silicone render is ideal for most modern and traditional buildings whether built from brick, blockwork or concrete. But, effectively it’s a question of how sound the building is and if there’s any other problems, such as dampness or structural, before applying silicone render.

Silicone render and silicone paint – what’s the difference?

A silicone render is a heavy-duty coat that is added to exterior walls for a strong, weather-proof finish. Silicone paint is a thin coat that can be applied to objects for aesthetic purposes. Silicone render has higher resistance and durability than silicone paint.

How do I pick the right colour for my silicone render?

Your silicone render colour choice needs to be one that enhances your building, the surrounding area and the style of your property. Factor in the color of your roof, windows and doors when you’re deciding on a color for your render. You can even see color charts and samples to determine if the finished product will look appealing.